Rural Contractor

Dairy farmer moves to big league

Hayden and Narelle Hillhortst moved from the Waikato to Canterbury last year in order to take on a bigger share-milking job.

With them went livestock - cows and kids - but also a computer-controlled, 6 Tonne SAM fertiliser Spreader.

They bought the SAM in preparation for their new property which has irrigation.

The farm near Ashburton they are now on has an 11-span centre pivot that discharges effluent from three spans. That led to the issue of how to fertilise the paddocks underneath when some of it was receiving effluent and some was not.

SAM solves the problem.

Hamilton-based Coombridge & Alexander is the manufacturer of SAM Spreaders. The company prides itself on making smart, simple and robust machines.

Computer-controlled SAM models have customisable options depending on the farmer's specific needs.

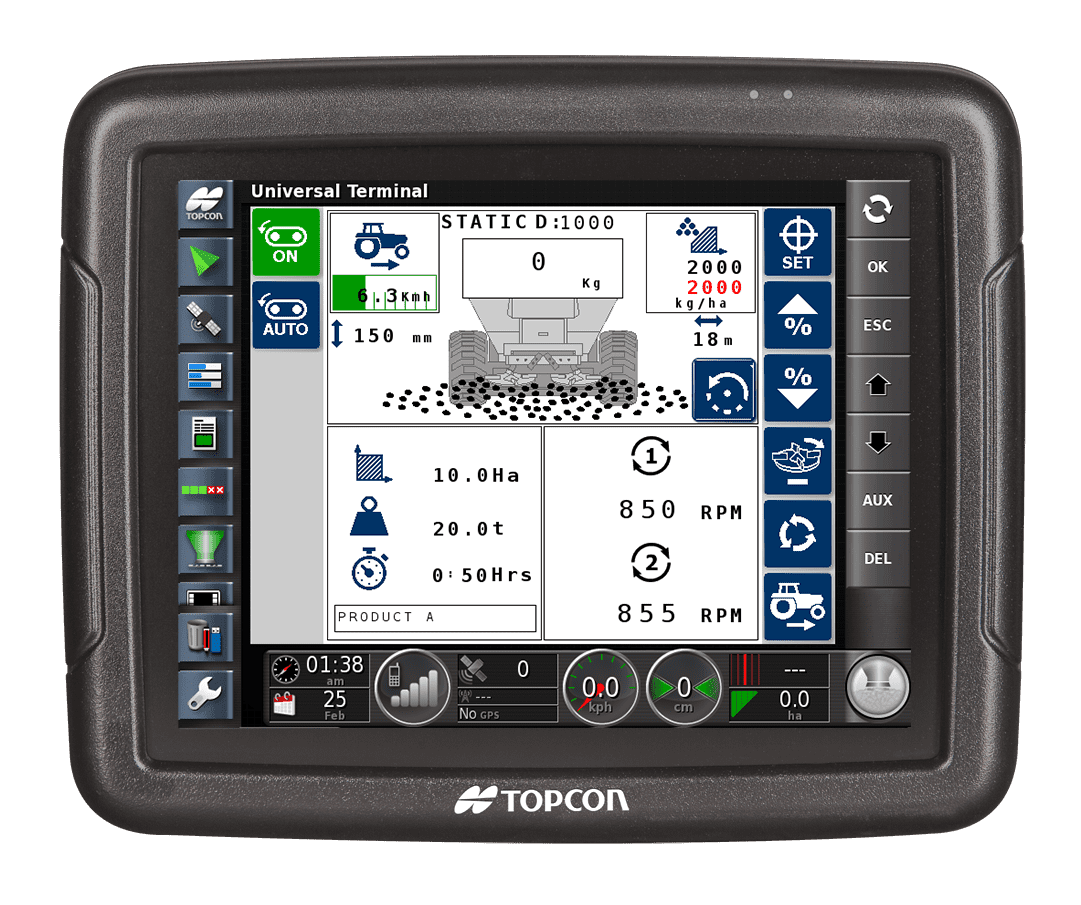

Hayden and Narelle chose the top level Topcon Athene control and monitoring system, which includes load cells and a GPS aerial. This allows them to be highly accurate, spread at variable rates and map everything they do.

So, back to those pivots. As Hayden drives across the paddock towing the SAM fertiliser spreader, it automatically changes rate so that paddocks under the effluent spans get, say, half the rate of urea.

SAM and Topcon have allowed Hayden and Narelle to keep their 'A' rating for auditing with their new, tougher regional council (although Hayden also credits the previous share-milker for setting up the property well for this).

"Coming to the South Island, it was important to have that level of control. We were nervous about it as it is a lot more intense here."

With the SAM/Topcon system, they have accurate control over spreading and the associated maps for proof of placement without having to slow down.

The Ashburton property is 220ha and it supports 800 milking cows. From August to the end of April Hayden follows the cows spreading two to three times a week.

This adds up to 2500 ha of spreading in a year. With his SAM Spreader he can travel at speeds up to 23kph.

Their tractor is 160 hp, but Hayden reckons that is overkill for the Canterbury farm because it is so flat. Topcon can supply an auto-steer system, but Hayden only has a light bar.

With his spreader, Hayden can apply at rates from 20 kg/ha up to 2 tonnes/ha for lime. The spread from the twin spinners is up to 20m for super.

The 6-tonne SAM spreader has a narrow belt for spreading urea, potash, super and lime. A wide-belt version is available for farmers who also want to spread chicken manure, compost or other organic products.

Hayden measures the density of a product, enters that into the monitor, covers a hectare and then knows from the load cells if it is accurate or not. Within two to three hectares it is spot on.

"Calibration is very accurate. I only do it with a new product, so normally once a month." Each product is then saved for future use.

The SAM Spreader is ISOBUS compatible and can either plug and play with the tractor's monitor or use its own X-25 8-inch touch screen.

Hayden uses the X-25 and finds it easy to navigate. "I am no computer genius and I can use it."

He and Narelle have specified their spreader with a tandem axle with upgraded tyres to reduce compaction.

Its bin holds 4.6m3 and is made of heavy-duty UV-resistant plastic. It resists corrosion, and fertiliser easily washes off.

The chassis is painted in several layers including a thermal arc process to resist corrosion and the rear parts are stainless steel for extended longevity.

Variable rate applications are easier because Hayden uses the Topcon Agricultural Platform (TAP), the new product from Topcon that is a genius-level filing cabinet floating in the cloud. This is an add-on that needs to be unlocked.

He can access his filing cabinet in the sky from his phone or computer.

"I draw up the maps at home through the TAP system. I can select the areas where it doesn't and set the different rates."

The information in map-form is sent to the tractor. When Hayden then opens the job, the spreader knows on GPS where it is, so it knows when to cut the spreading rate back and when to go up again.

At any time Hayden can use TAP to pull up a map of any paddock onto his phone and see what product was applied and when.

TAP is not just for spreaders and not just for Topcon products. It can deal with information from most GPS providers. It incorporates a range of farm data onto maps, to make it meaningful even at a glance.

Anything from Hayden and Narelle's SAM Topcon controlled spreader is uploaded and integrated automatically.

The irrigators use a different system and Hayden enters that into TAP manually. If Hayden gets a sprayer then that will be linked in with the TAP filing cabinet too, keeping all his information in one place. If you are not of the generations that think computers are a fun necessity of life, then a new system can be daunting. The team effort from Coombridge & Alexander and Topcon has produced a product that allows Hayden and Narelle to meet the dual goals of production and compliance.

"They understood what I was trying to do and gave me the result I wanted. We are happy with the spreader and can't fault it."

- e-Wagon launch

- New pricing app for SAM dealers

- Accurate & connected

- Protect your gear with the SAM coating…

- SAM Footprint

- Local manufacturer builds spreader for orchards

- Dairy farmer moves to big league

- e-Spreader - e for easy!

- Sharp design - reinvented

- Celebrating 50 years at the Fieldays

- New digs for SAM!

- New kids on the block

- Have your say on SAM’s next donation

- Steel decks on every SAM Trailer

- Stainless side-feeds a breeze to maintain

- SAM continues to make its mark

- SAM's the man

- Corrosion resistant paintwork

- More stainless. Less worries.

- Accuracy and testing for SAM Spreaders

- Kiwi favourite marks 75 years in business

- SAM Computer Control

- Meet the NEW SAM Orchard Spreader

- Made in NZ...SAM Machinery

- Topcon Tips

- Shout out to SAM - 75 Yrs!

- Review: SAM Orchard Spreader

- It's Isobus baby!

- Proudly NZ-Made

- Proven to last the distance

- Easy-to-use SAM orchard spreader gives BOP contractors…

- SAM Machinery welcomes new head

- What's the go at Fieldays