e-Spreader

Simple integrated accuracy.

Introducing our latest innovation - the SAM e-Spreader. Any SAM Spreader can be upgraded to an e-Spreader at the time of build. The floor speed is controlled from a screen in your tractor cab. This replaces the manual drive. You can set your rate easily from in your cab and get your spread rate very accurate.

The SAM e-Spreader is easy to calibrate and every e-Spreader is load cell ready. Integrating load cells is the only way to get true accuracy because you are weighing your product. This technology means the correct application rate is applied regardless of changes in forward speed.

It also integrates easily with third party GPS systems such as TracMap. You can see how many hectares you have covered from the screen and the weight you have applied. This live data means proof of placement is easy. If you are already using a third party tracking system you don’t have to reinvent the wheel.

80 - 90 l/min of oil flow from your tractor is preferred.

Smart Features

-

Watch the SAM e-Spreader in action

This video shows James chatting about his NEW SAM e-Spreader. Its e-Rate controller controls the floor speed from in your tractor cab. This replaces the manual drive. You can set your rate easily from in your cab and get your spreading very accurate.

-

e-Rate controller in your cab

The e-Rate controller screen is mounted in your cab. Setting your spread rate is simple – just key in your spread rate, your product density and spread width. The reliable European hardware is from Germany coupled with innovative Kiwi software (shown here with TracMap).

-

Border control & Bulk unloading

Extra functions such as bulk unloading and border control are included as standard. Border control reduces spinner speed on the right hand disk which decreases spread width. This is helpful for spreading beside borders and waterways.

-

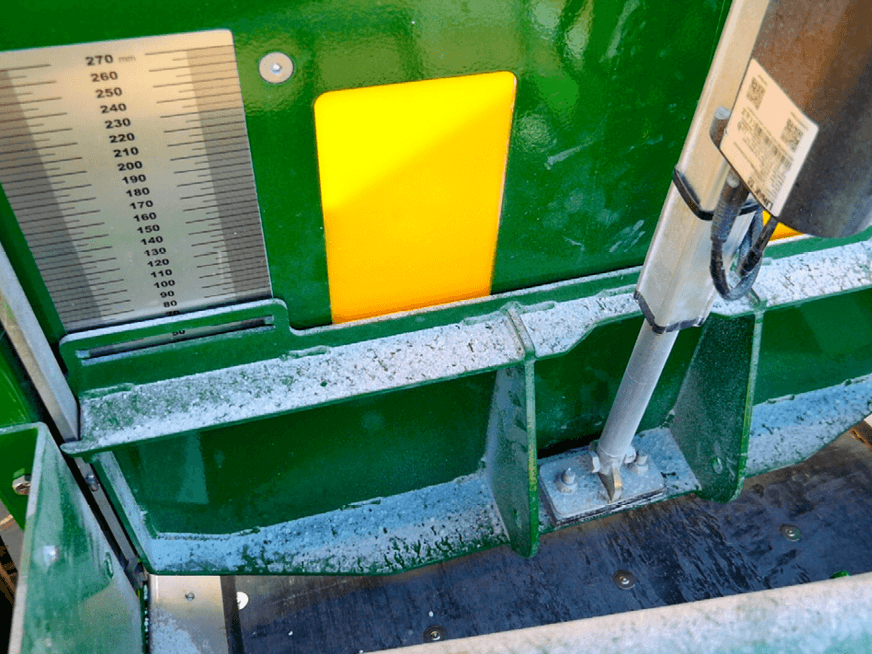

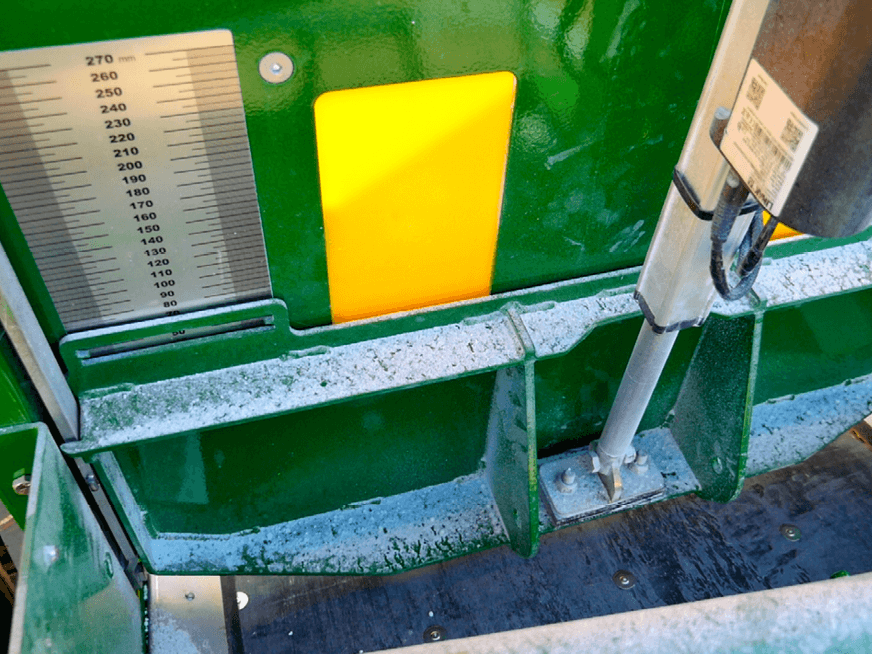

Load cell integration

Integrated load cells are standard. They give you improved accuracy as you are weighing the product in your bin.

-

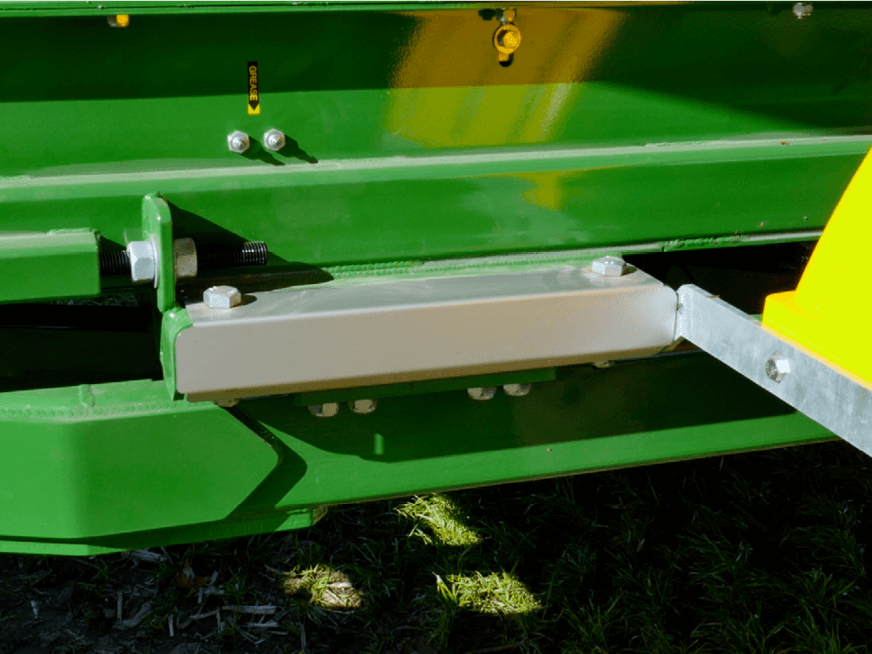

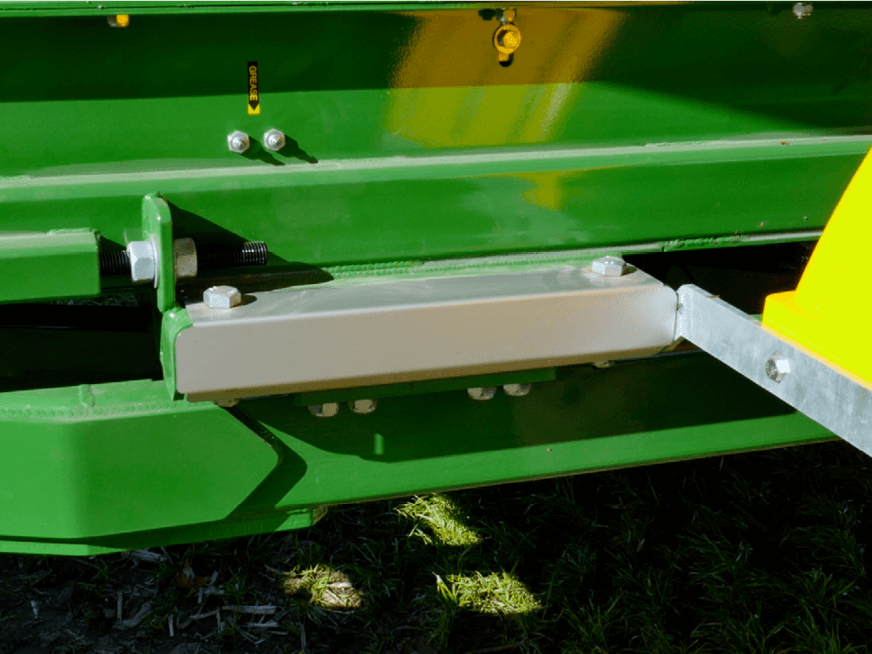

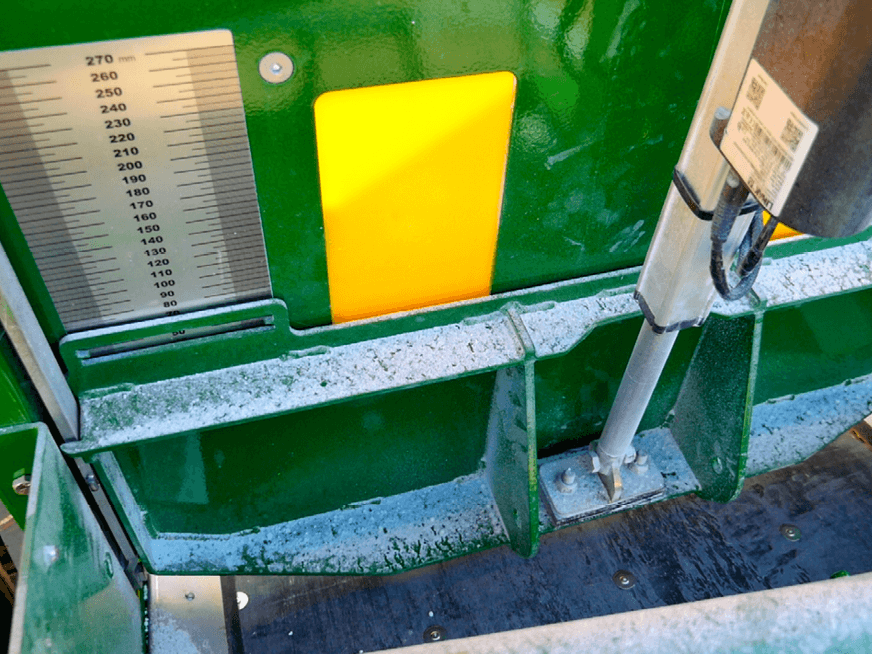

Electric back door

An electric back door replaces the manual winding of the back door jack. The height is simple controlled from your screen. Also handy for closing your back door when you are driving down the race so you are not losing any product out the back.

Optional Extras

- Electric back door

- Load cell integration

Electric back door

An electric back door is a new optional extra and replaces the manual winding of the back door jack. Simply key in your rate, density and width then the back door moves to the appropriate height for you.

Also handy for closing your back door when you are driving down the race so you are not losing any product out the back. There is a simple manual override function built in.

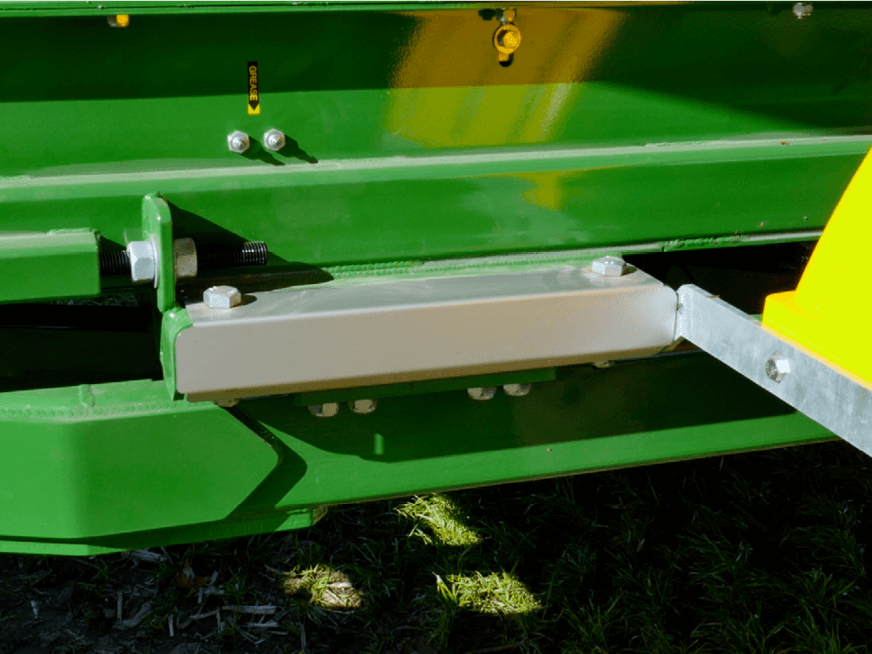

Load cell integration

Adding load cells to your e-Spreader is recommended. They give you improved accuracy as you are weighing the product in your bin.

All e-Spreaders are load cell ready.

Smart Choices.

Find out which finer details are right for you.

-

What advantage does Topcon have over the e-Spreader?

It is ISOBUS compatible so can plug directly into your tractor (if compatible). Proof of placement is integrated into the system without relying on third party reporting.

It also has some nifty extra features such as dynamic rate control, mapping, light bar and sectional control. We’ll customise the right set-up for your requirements. Find out more.

-

What advantage does e-Spreader have over the Topcon?

The cost to purchase is lower.

The e-Spreader integrates well with third party mapping systems such as TracMap. So if you are already running a system for proof of placement, you can stick to what you know.

-

Which Spreaders can be made into e-Spreaders?

All Fertiliser Spreaders (narrow belt) or Combo Spreaders (wide belt) can be upgraded to e-Spreaders at the time of build. From the smaller 4, 5 & 6 Tonne SAMs right up to the larger 8 & 9 Tonne models.

Specifications

- Interface e-Rate controller (German hardware)

- Screen size 4.3"

- Computer controlled rate Yes

- Load cell ready Yes

- Plugs in to third party GPS Yes

- Proof of placement Requires third party GPS

- Border control Yes

- Volumetric rate control Yes

- Static rate control Yes