9 Tonne Combo

Tough and versatile.

With the same practical design and easy to use operation that all SAM’s are known for, the SAM Combo Spreaders (800 Series) provide extra versatility around what you are able to spread.

They are capable of spreading chemical fertiliser including; superphosphate, urea and lime. But will also spread most organic product like chicken and pig manure, screw-pressed effluent and sand.

Available with capacities of 4, 5, 6 and 8 tonne. All come standard with an 800mm floor belt and are generally tandem axle.

Keep it simple with a standard hydraulic clutch to ground drive, or upgrade to the latest smart, accurate computer control system with weigh scales.

Smart features

-

More stainless for longevity

Majority stainless at the rear of the machine, extends longevity of gear where you need it most. The stainless discs are run via enclosed stainless spinner tubes and two well-proven hydraulic motors. Easily adjustable tapered roller bearings keep disks tight.

-

Corrosion resistant paintwork

All chassis's on SAM Spreaders have seen a new evolution of painting procedure. This is for extra corrosion protection. Firstly a steel grit abrasive blast then a thermal-arc pure zinc spray, a primer followed by a final two-pot epoxy top-coat. It is mega tough stuff!

-

Strong plastic bin

The polyethelyne plastic bin has proven to be extremely reliable. They are strong, corrosion resistant and UV-stabilised. Fertiliser also slips down the sides and washes off easily when you are cleaning your gear.

-

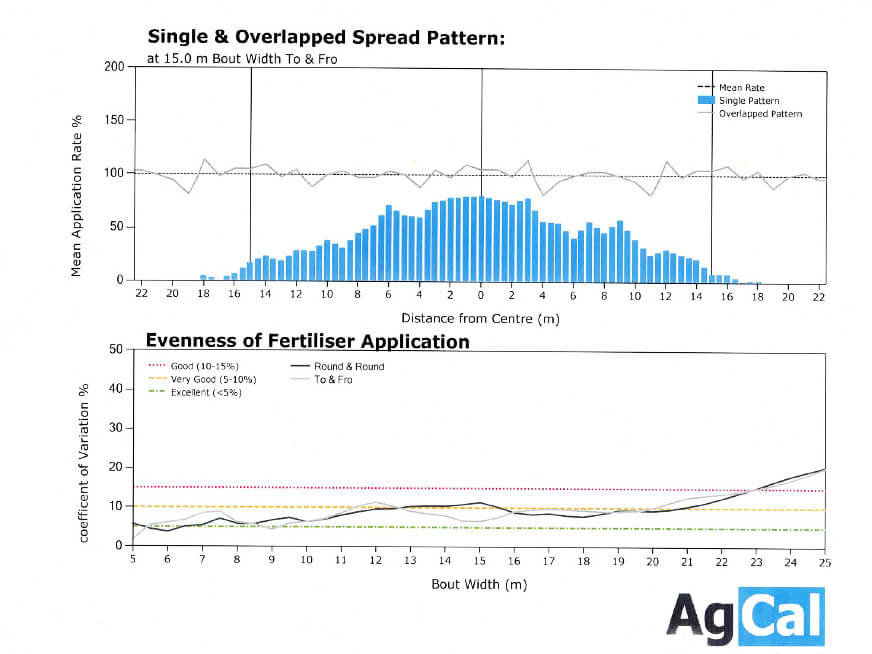

Even, accurate spread

The SAM twin spinner disc design gives an accurate and consistent spread pattern across a range of products. Quick and simple rate setting is by adjusting the rear door.

-

Load weigh scales

You can add scales to your spreader. This gives simple, accurate electronic weighing of your fertiliser. And can be zeroed out any time. More info below.

-

Computer control system

You can also add a computer control system to replace the standard ground drive. This gives hydraulic floor speed rate and control. More info below.

-

Rubber floor-belt (800mm wide)

Provides a positive non-slip feed of fertiliser onto the spinner discs. A smooth two-ply rubber floor-belt is riveted to hot-dip galvanised steel bars, welded to high-tensile chain. Stainless skirts run alongside.

-

Material agitator

This optional extra is designed to break up and crumble organic material like screw pressed effluent. This improves the flow to fall consistently onto the spinner discs.

-

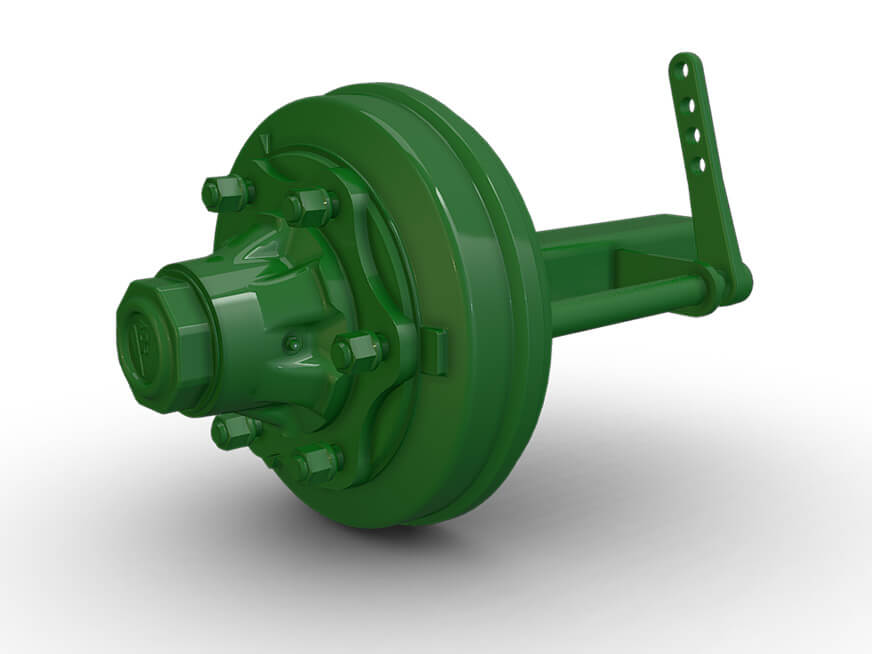

Remote axle greasing

Remote axle greasing saves you time and effort by giving you access to all axle greasing points. They are raised together in a bank in an easy to reach location. A very effective way to improve machine maintenance, without having to jump under your machine. So keep that gear greased - no excuses!

-

App for verifying rates

A great check against your back door setting to verify exactly what you are spreading. This is for use with Spreaders fitted with load cells. Contact us and we will send you the link. Currently Android only.

-

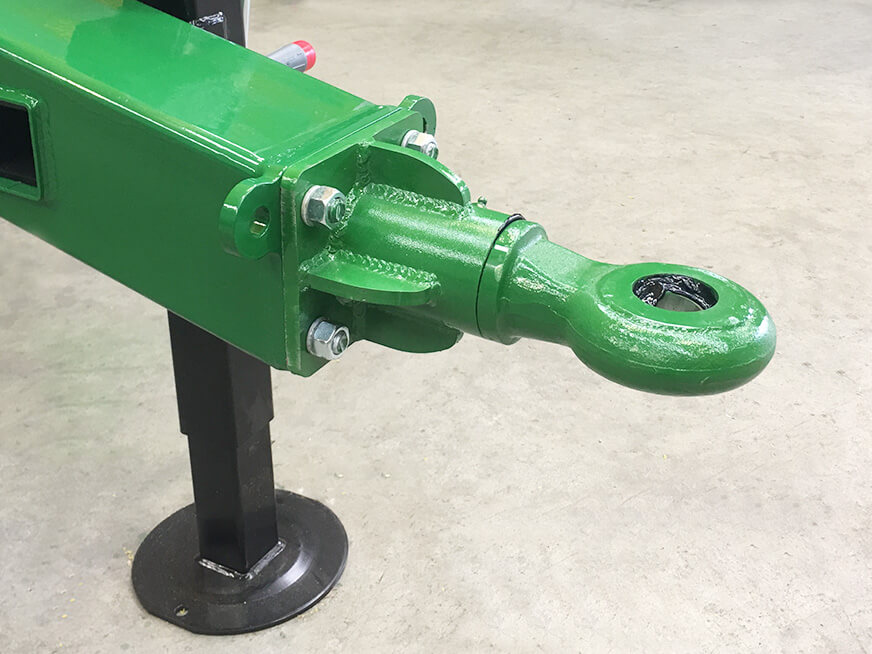

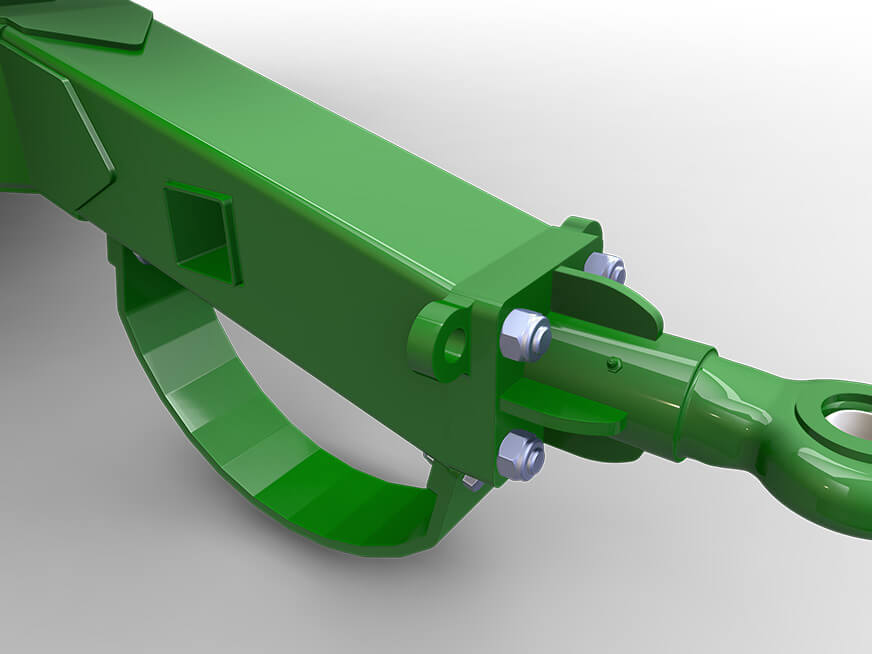

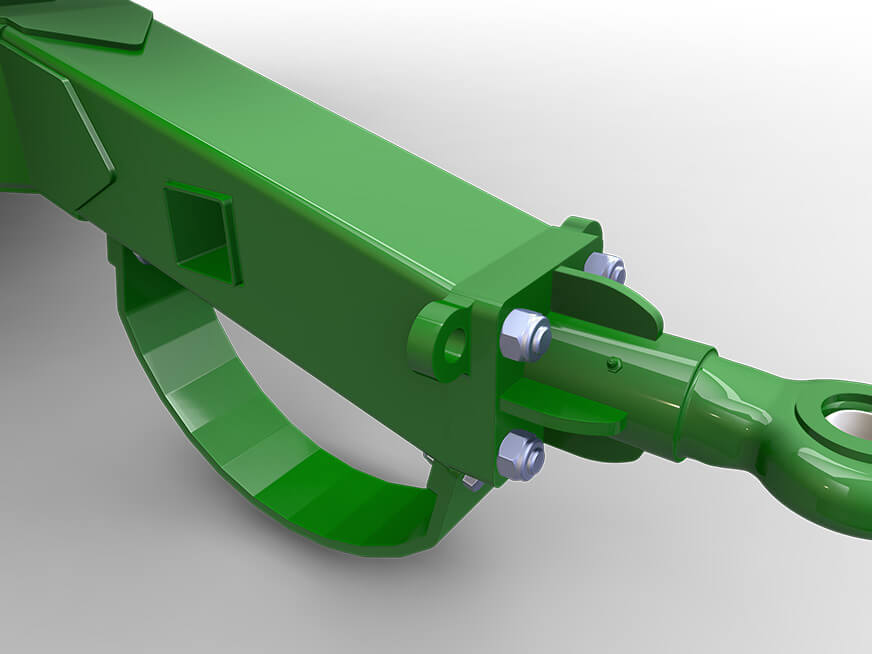

Swivel coupling adds stability

Smaller spreaders come standard with a fixed coupling. The 6, 8 and 9 tonne spreaders come standard with a heavy-duty swivel coupling. They are great for varied terrain. You can choose a donut eye for coupling with a quick hitch or the insert option for tractor coupling.

-

Safety steps

Provide strong, stable stepping points and grip bar for extra safety. They are included as standard in the 8 & 9 Tonne models.

Optional extras

- Roll-top cover

- Internal mesh

- Load cells

- e-Spreader

- Topcon control (ISOBUS)

- Brakes

- LED Lights & flags

- Material agitator

- Mudguards

- Tyre upgrade

- Skid

- Auto drive chain tensioner

- Stainless steel hydraulic hose fittings

Roll-top cover

Upgrade to an easy to use roll top cover. This is a simple canvas, frame and bungy system. The handle rolls your cover up, tucked out of the way when not in use.

It is mounted on the rear of the machine so you can load from both sides.

Internal mesh

This mesh fits inside your bin. It stops large objects dropping down and damaging the belt and gear. Great for spreading crusty Urea.

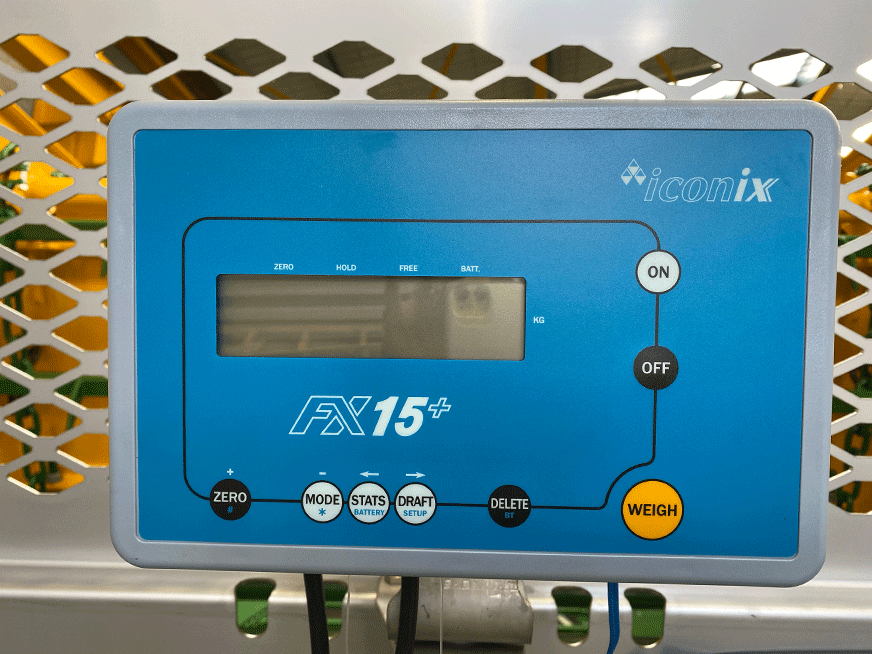

Load cells

Manual drive spreaders

Load cells give an accurate measure of the weight of product in the bin. They can be zeroed at any time.

A simple calculation of the weight of product spread, divided by the area covered, gives you the spread rate (in kg/ha). Many new tractors have an inbuilt display that will give area covered at certain spread widths.

A fixed Iconix FX15 display unit is supplied with all manual SAM machines fitted with weigh scales. It is mounted to the front of your spreader.

A simple App for Bluetooth viewing on your mobile is also available (currently Android only). This App allows you to verify your spread rate at any point in time.

Computer drive (e-Spreader & Topcon)

You can also add load cells to any computer controlled machine. Most are spec'd this way. It is really the only way to get true accuracy because you are actually weighing the product in the bin.

e-Spreader

Any SAM Spreader can be upgraded to an e-Spreader at the time of build. The floor speed is controlled from a screen in your tractor cab. This replaces the manual drive. You can set your rate easily from in your cab and get your spread rate very accurate.

The SAM e-Spreader is easy to calibrate and every e-Spreader is load cell ready. Fitting scales is the only way to get true accuracy because you are weighing your product. This technology means the correct application rate is applied regardless of changes in forward speed.

It also integrates easily with third party GPS systems such as TracMap. You can see how many hectares you have covered from the screen and the weight you have applied. This live data means proof of placement is easy. If you are already using a third party tracking system you don’t have to reinvent the wheel.

80 - 90 l/min of oil flow from your tractor is preferred.

If you are wanting a computer controlled alternative that is ISOBUS compatible, check out Topcon control.

Topcon control (ISOBUS)

Adding the new Topcon computer control system means the correct application rate is applied regardless of changes in forward speed or changes in product density.

By adding the load weigh scales too, the weight of product in the bin is integrated, allowing dynamic rate control. It is continuously using the weight of product in the bin to check spread rate accuracy.

This computer control system is ISOBUS compatible so can function with the majority of modern tractor consoles.

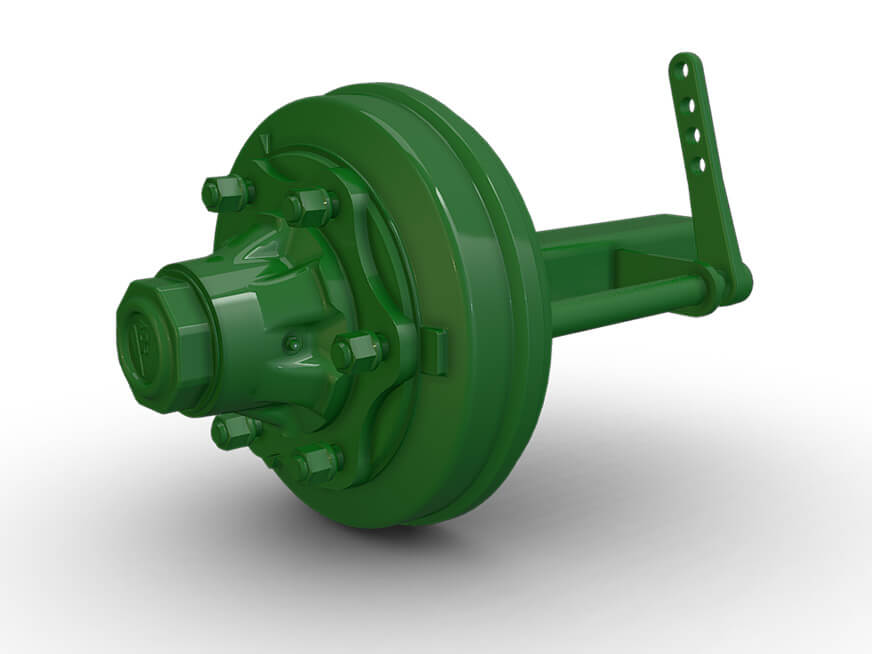

Brakes

Brakes are available for tandem axle machines. They are usually located on the front hubs only. The brake system chosen had been well-proven over the years and is very reliable.

LED Lights & flags

If you are using your machine on the road you will need a set of lights and flags. The flexi mounting boards are made from durable plastic, hardy for knocks and general wear and tear.

Weatherproof lights are LED and plug directly into your power source.

Material agitator

The material agitator is designed to break-up, lift and tumble materials in a gentle but thorough blending action. This process, ideal for organic material and manure, allows for consistent flow onto the spinner disks.

Mudguards

Mudguards are moulded from UV-stabilised polyethylene, and resistant to most chemical and organic fertilisers. Debris chips to the chassis and running gear are reduced and less cleaning required.

Mudguards come standard on all tandem axle models below 8 tonne. They are an optional extra for 8 and 9 tonne models. POA

Tyre upgrade

We have tough high performing tyres to suit any application. They are chosen for their quality and durability.

We can change tyre sizes to suit your specific needs. The 5 tonne tandem combos use 11.5 x 15.3 tyres but these can be upgraded to larger 400 x 15.5 tyres. The 400 x 15.5 tyres are standard on the 6 tonne combos but can be upgraded to the 500 x 17 tyres.

500/60 x 22.5 tyres are standard on all 8 and 9 tonne models. These larger tyres can be excellent if you have softer, wetter conditions.

Custom options are also available POA.

Skid

If you are using your machine with a quick hitch you will want to include a skid on the drawbar.

Please also specify that you would like a donut eye on your tow eye.

Auto drive chain tensioner

Drive on-road without removing drive chain.

Stainless steel hydraulic hose fittings

Higher grade hydraulic hose fittings for rust protection.

Smart Choices.

Find out which finer details are right for you.

-

Standard ground drive SAM Spreaders

Ground driven Spreaders have a floor speed that is directly proportional to your forward speed (driven from a chain off the wheel).

Should I go for a Standard ground drive Spreader (400mm wide floor mat) or a Combo Spreader (800mm wide floor mat)?

SAM Fertiliser Spreaders (400mm wide mat) are capable of spreading all processed fertiliser including superphosphate, urea and lime.

SAM Combo Spreaders (800mm wide mat) are capable of spreading all processed fertiliser including; superphosphate, urea and lime. And they will also spread most organic products like chicken and pig manure, screw-pressed effluent and sand.

Is there anything the Combo Spreaders won’t spread well?

In general your product needs to be fairly free-flowing to spread properly. A good test is to dig a spade into your product from the side, if it falls in on itself then it should flow through the machine nicely.

At the other end of the scale, anything too wet e.g. effluent, may leak out the sides of the bin.

-

Standard ground drive SAM Spreaders + proof of placement

What is proof of placement and how do I get that?

Proof of placement means you are able to record and retain proof of what you have been spreading, where you spread it, how much, and when. Different councils may have slightly different regulations for how to comply.

Proof of placement can be achieved in a number of ways. A standard ground driven SAM Spreader can achieve proof of placement with any GPS mapping systems e.g. Topcon, TracMap or similar. Or, if regulations allow, manually recording what you have been spreading, where you spread it, how much and when, may also be sufficient.

When using the computer controlled models you manually key into your screen what you are spreading and the rate. The details will be recorded in your mapping program. While you are spreading the mapping program will record the track of the spreader in the paddock, to be uploaded to a cloud based server or local computer for later reference. Both Topcon and TracMap offer a hosting service to store your maps.

We offer two integrated proof of placement options that can be purchased at the time of your build. The e-Spreader and Topcon Control. These replace the manual chain drive with a hydraulically driven floor controlled from a screen in your cab (both are load cell ready – meaning load cells can be added at any time).

Why would I want to add load cells to my standard ground drive Spreader?

Load cells are an optional extra. They give an accurate measure of the weight of fertiliser in the bin and can be zeroed at any time. As standard, an Iconix FX15 display unit is supplied with machines fitted with load cells. This is fixed to the front of your Spreader.

Load cells need be added to your machine at the time of build. They cannot be retrofitted to Spreaders.

Can I view the weight of fertiliser in the bin on my phone?

To support load cell weighing, we have created a simple mobile phone App. This App means you can view the accurate weight of product in your machine on your phone.

The App will also allow you to to check your rate per Hectare with an easy and quick calibration process. The App works off Bluetooth, is simple to use and free to download. It is currently for Android only.

-

Computer controlled drive SAM Spreaders (hydraulically driven)

I’m thinking about buying a computer controlled SAM Spreader - what is this?

Any of our Spreader models can be manufactured with computer control installed to replace the standard ground drive. This computer operates a hydraulically driven floor-belt. Application rates are adjusted easily from the screen inside your cab.

The screen requires a few quick inputs from you; fertiliser density, spread width and spread rate, followed by a quick calibration step. Then you are away.

Computer drive needs be added to your machine at the time of build. They cannot be retrofitted to Spreaders.

There are two options: the simple, accurate e-spreader; or the more advanced Topcon control.

What is the e-Spreader?

Any SAM Spreader can be upgraded to an e-Spreader at the time of build. The floor speed is controlled from a screen in your tractor cab. This replaces the manual drive. You can set your rate easily from in your cab and get your spread rate very accurate.

The SAM e-Spreader is easy to calibrate and every e-Spreader is load cell ready. Fitting scales is the only way to get true accuracy because you are weighing your product. This technology means the correct application rate is applied regardless of changes in forward speed.

It also integrates easily with third party GPS systems such as TracMap. You can see how many hectares you have covered from the screen and the weight you have applied. This live data means proof of placement is easy. If you are already using a third party tracking system you don’t have to reinvent the wheel. Border control is included.

If you already have an ISOBUS compliant tractor or want the likes of sectional control and the ability to store and report your date check out Topcon control.

What are the advantages of having a computer drive?

- Application rates can be set from the screen inside the cab

- Spreaders can travel very slowly while spreading at a very high rate (spreading shavings into sheds etc.).

- The integration of load cells gives pinpoint precision on the weight of fertiliser in your bin at any time (Optional extra)

- Border control gives protection for your headlands

- Spreaders can be unloaded without moving forward

- It is easy to extract information for proof of placement record keeping

- Proof of placement mapping can be included with the Topcon computer control option, or by utilizing your existing GPS with the e-Spreader

What are the disadvantages of computer drives?

- Higher purchase cost

- Tractor must have higher oil flows (approximately 90 litres per minute)

- Most suited to operation behind one tractor as the power supply is hard-wired. Unless you

- Operators require more training

- Electronics fitted on computer controlled Spreaders require more care i.e. no waterblasting near computer enclosure.

Can I add computer control to my Spreader without adding load cells?

Yes you can. This is called Volumetric rate control.

Computer control can be used as a simple rate controller. Either by entering a known product density or selecting the fertiliser product from a pre-defined list.

Spreader functions like spinner speed and border control are all monitored and operated through your screen.

The benefit of volumetric rate control is that you are saving on the cost of the load cells. However you are not getting the added benefit of a continuous double check of the weight of product in your bin.

Why would I go for the Topcon computer control with integrated load cells (using my tractors own ISOBUS screen)?

This is Dynamic or Static rate control. It includes integrated load cells and can be managed from the tractors own ISOBUS screen.

This set-up includes fully hydraulic floor speed and rate control. It measures the weight of product in the Spreader on the go. The floor speed is automatically adjusted to achieve the correct application rates dynamically (on the move).

This advanced control means extra precision. The accuracy of rate is as high as 99% of the target rate. You are getting automatic rate calibration and gaining maximum value from what you are spreading.

Most new tractors are ISOBUS compatible, meaning the system can plug straight into your tractor and can be controlled from your existing console. This can save the cost of a second display.

Border control functionality is included. Border control when switched on reduces spinner speed on the right-hand disk which decreases your spread width on that side. This is helpful for spreading beside boundaries and waterways.

An auto shut-off function (sectional control) is also available at headlands or cross over areas, meaning no areas will receive a double application.

Why would I go for full Topcon computer control with integrated load cells, X25 screen and GPS aerial?

This is Dynamic or Static rate control. It includes load cells, a GPS aerial and our Topcon X25 screen for inside the cab of your tractor.

This set-up also gives you the above functionality (computer controlled rate application, border control, sectional control) as well as a GPS aerial for proof of placement, light bar and field mapping of your jobs.

Record all your spreading details for improved traceability and record keeping.

This set-up also means you can swap tractors easily by simply swapping the screen across.

Can I use my own GPS aerial?

Just call us up and let us know what kind of aerial you are using and we will let you know if it is compatible.

What is TAP?

TAP stands for Topcon Agricultural Platform. It stores your inputs for mapping and proof of placement reporting. It is all about easy access to your data. There will be an upgrade cost for this. Call us and we can talk you through it.

What is variable rate spreading?

This means changing spread rates automatically on the move from preplanned fertiliser mapping uploaded to the computer. Call us anytime if you want to chat further about this add-on.

Do I need an inline oil filter with my computer control Spreader?

An inline oil filter is recommended with Topcon controlled Spreaders. This filters the oil prior to getting into the system. It is a good idea to protect the hydraulics, cartridges and valves of your machine.

Who are Topcon and why are they so good?

Topcon are an international tech company who bought RDS out in 2012. Their technology has been proven in international markets for decades.

They have engineering, manufacturing and development facilities in Europe, the United Kingdom and Australia. There are over 2,000 Topcon employees worldwide, including a large research and development team, so their products are always innovating. The computer control system has been well tested in the field and has been popular on farms for years.

Elements are customisable to suit your individual needs. The set-up integrates well with our Spreaders by being ISOBUS compatible, intuitive to use and fully integrated with load cells.

-

How much of each fertiliser type will my SAM Spreader hold?

4 Tonne Spreader - 3.2m3 (Fertiliser), 4T (Superphosphate 1.3/m3 density), 5.5T (Lime 1.7t/m3 density), 2.6T (Urea 0.8T/m3 density).

5 Tonne Spreader - 3.9m3 (Fertiliser), 5T (Superphosphate 1.3t/m3 density), 6.6T (Lime 1.7T/m3 density), 3.1T (Urea 0.8T/m3 density),

6 Tonne Spreader - 4.6m3 (Fertiliser), 6T (Superphosphate 3T/m3 density), 7.7T (Lime 1.7T/m3 density), 3.7T (Urea 0.8T/m3 density)

8 Tonne Spreader - 6.5m3 (Fertiliser), 8T (Superphosphate 1.3T/m3 density), 10T (Lime 1.7T/m3 density), 5.2T (Urea 0.8T/m3 density)

9 Tonne Spreader - 7.6m3 (Fertiliser), 9T (Superphosphate 1.3T/m3 density), 11T (Lime 1.7T/m3 density), 5.9T (Urea 0.8T/m3 density)

Specifications

- Axle type Tandem-axle 80mm

- Axle capacity 16,000kg

- Wheel type 500/60 x 22.5

- Jack type 70mm screw jack

- Overall length 6.1m

- Overall width 2.75m

- Overall height 2.38m

- Bin width 2.1m

- Bin length 4.1m

- Capacity 7.6m3

- Superphosphate 9T

- Lime 11T

- Urea 5.9T

Fast central support service

Our SAM range is backed by a quick and efficient support service from central Hamilton. The team are also available for technical help should you need it.

Our guarantee

We deliver quality products and stand by them. All Spreaders go through rigorous quality and accuracy testing. They also have a comprehensive warranty.